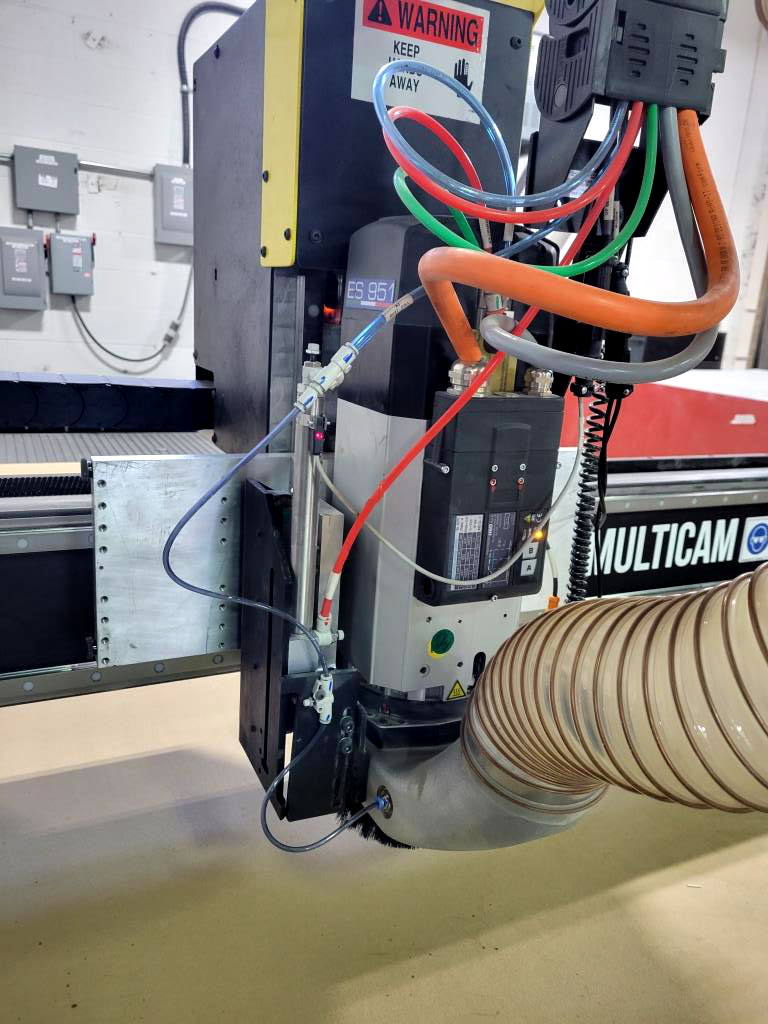

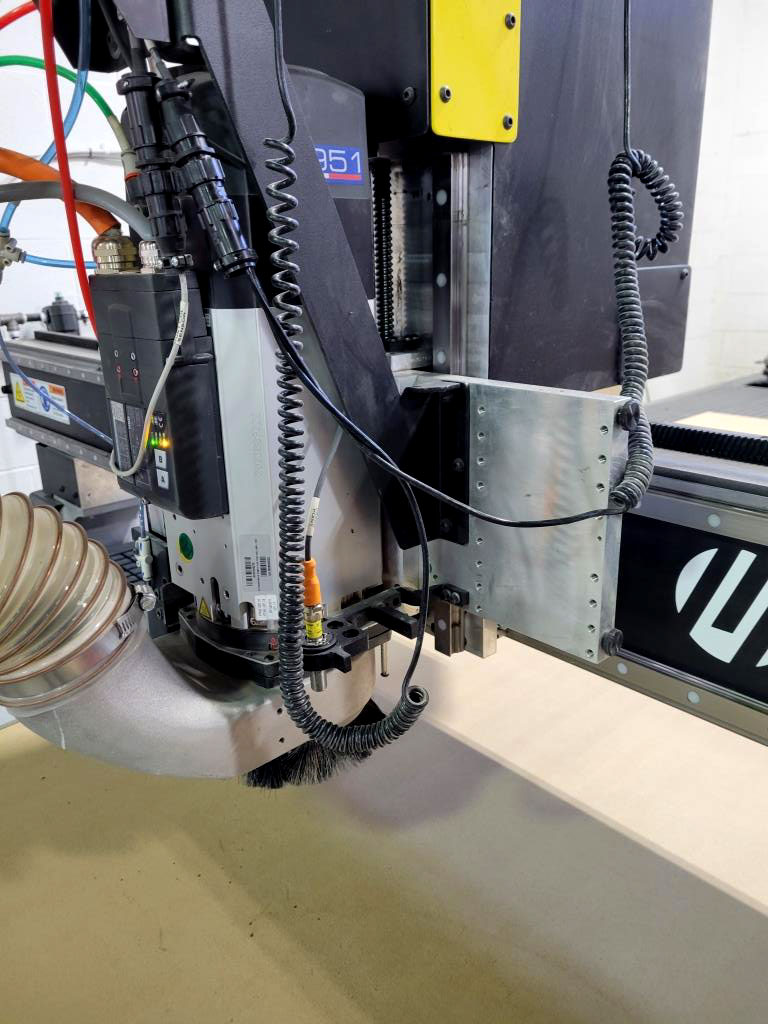

- Installation Type: Apex 1R CNC Router

- Website: www.protectolite.com

Toronto ON based Protectolite Composites Inc has recently invested in a MultiCam Apex 1R CNC router from Mikon Machinery Group Inc to assist in growing their fiberglass/composites machining business. Protectolite has been established for over 60 years as one of the largest suppliers of composite materials and machined components in the city. Customers include electrical utility companies, TTC, Transformer manufacturers, and users of the SMC Molding process.

Protectolite has traditionally used their Flow waterjet to profile cut their materials, but found that the speed and operating cost of waterjet could not match CNC router cutting. While waterjet certainly has its’ place (and Mikon Machinery provides waterjet equipment for the right applications), for accurate, 2D cutting of fiberglass profiles to precision sizes, it is hard to beat a CNC router with a vauum table. The operating costs per hour are a fraction of what a waterjet costs to run, and cutting feedrates are much faster.

The CNC router from Mikon Machinery utilizes precision coated carbide cutting tools that have wear resistant coatings to deal with the abrasive nature of fiberglass/composite sheets. Dust collection is also part of the package in order to minimize the effects of dust being released into the ait, and Protectolite staff have been trained to properly clean and maintain their new CNC router to keep fiberglass dust away from critical motion system and spindle components.

Mikon Machinery provided full installation, training, applications support, as well as ongoing tooling and fixturing assistance. We are proud to have partnered with an established supplier to the composites industry