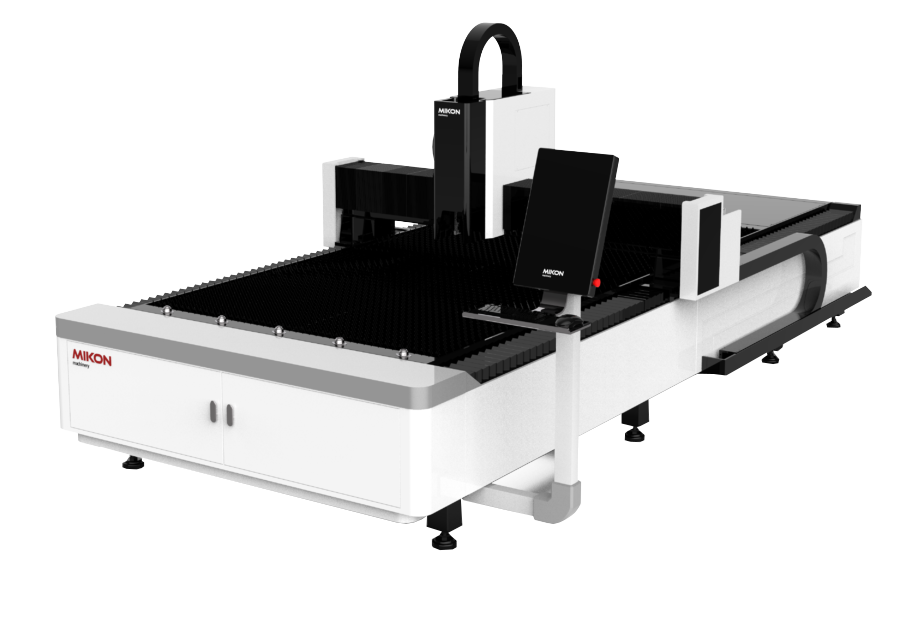

The ML Series CNC Fiber Laser, a 1500W affordable open-concept machine, excels in light sheet metal, HVAC, and commercial kitchen applications with finer details and faster cycle times than similar plasma machines.

Steel cabinet enclosure

Steel slats for material support

flat screen controller and keyboard

high speed alumnum gantry

pressurized lubrication

precision rack and pinion motion system

| 1500mm x 3000mm |

Cypcut Operating software

The machine frame structure is an important factor affecting the cutting speed, precision, stability and durability of the fiber laser. It also plays a key role in keeping the cutting head in position atmaximum speeds and is critical to a fiber laser’s cutting dynamics. This is why Mikon Machinery fiber lasers utilize a metal honeycomb structure welded by a number of rectangular plates. Stiffeners are arranged inside the tubes to increase the strength and tensile strength of the machine frame, it also increases the resistance and stability of the guide rail to effectively avoid the deflection of the frame, which can cause problems with

The laser head is the second important part of any laser cutting machine, the High Precision Laser Head is a fiber laser cutting head engineered for medium and high-power industrial applications. The cutting head has a built-in motor drive unit through the linear driver, and the focusing lens can automatically change the position in the range of 20mm. The user can set the focus continuously through the program to complete the rapid piercing across a wide variety of materials and thicknesses. Optimized optical design, combined with digital height sensor can make cutting more efficient. Dual water-cooled design allows the laser head to work continuously and consistently at high power overlong periods of time.

All electrical components and laser source are built-in to the independent control cabinet with a dust-proof design to prolong the lifespan of the electrical components. The control cabinet is equipped with air conditioner for automatic constant temperature. This can prevent excessive temperature damage to components in summer.

Laser Software Interface: CypCUT Plane Cutting Software with Nesting utility for material savings. Mounted touch screen monitor and remote control for convenient interfacing

High precision, long life, can provide rigorous support for quenching helical gears and grinding helical gears, so that the load drive structure is compactand can effectively reduce the driving torque.

This 1500W laser is specifically tailored for precision cutting of light sheet metal, ideal for applications in HVAC and commercial kitchen fixtures. Its superior design allows for detailed, finer cuts at accelerated speeds, surpassing the capabilities of traditional plasma machines. Capable of using shop air, Oxygen, or Nitrogen as assist gases, the ML Series CNC Fiber Laser efficiently processes various types of sheet metal with ease. This adaptability makes it an essential tool for industries requiring high-quality, precise, and quick cutting of diverse metal materials.

Steel

Stainless Steel

Galvanized steel

Aluminum

Designed to excel in environments such as HVAC, Commercial Kitchen Manufacturing, and Light Sheetmetal Fabrication, this laser cutter brings a new level of efficiency and precision to these industries. Its ability to cut intricate designs at high speeds makes it ideal for producing complex parts in HVAC systems, durable fixtures in commercial kitchens, and versatile components in light Sheetmetal applications. With its superior performance over plasma machines, particularly in finer details and faster cycle times, the ML Series CNC Fiber Laser enhances overall productivity and quality, making it a key asset for a wide range of manufacturing needs.

HVAC

Commercial Kitchen Manufacturing

Light Sheetmetal

IDY Print, a veteran in visual communication and media with over two decades of expertise in Mississauga, has recently upgraded its capabilities with the addition of a ML3015E Fiber Laser machine. This new equipment marks a significant investment in their production technology, promising to further enhance their graphic solutions.

Open concept, affordable 1500W laser designed for light Sheetmetal, HVAC and commercial kitchen fixture applications. The ML Series CNC Fiber Laser allows for cutting finer details and faster cycle times than similarly priced plasma machines. Set up to use shop air, Oxygen or Nitrogen assist gases, the ML fiber laser can quickly and easily cut Sheetmetal parts. For immediate assistance or queries, feel free to call us at (844) 579-8398 or fill out our consultation form, and our specialists will get back to you as soon as possible.

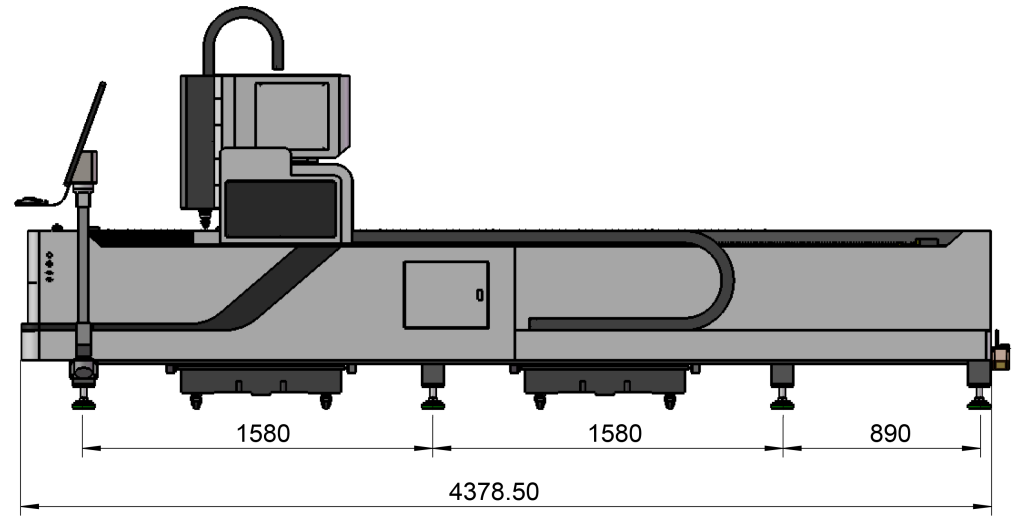

Get a detailed look at the ML Series CNC Fiber Laser with our downloadable machine layout. Easy and quick, it’s your first step to seamless integration!

Ensure your CNC fiber laser machine operates at peak efficiency with Mikon Machinery’s premium tooling and consumables. We provide a wide range of CNC tools including laser cutting heads, nozzles, lenses, and protective windows designed to optimize cutting precision and extend machine life. Our selection also includes fume extraction systems, assist gases (such as nitrogen and oxygen), and consumables to maintain clean cuts and smooth operations. For cutting metals like steel, aluminum, and brass, our fiber laser machines and parts deliver unmatched accuracy and speed.

Sign-up for our newsletter!

Select the newsletter category you would like to receive

Machines

Contact Us

Copyright Mikon Machinery ® LLC 2024. All Rights Reserved. | Designed by CNC Marketer

Join Our Newsletter

We know your inbox is full of sales pitches. We take a different approach. Our emails focus on what matters to you, like choosing the right spindle HP and essential maintenance tips. For joining us and staying informed, simply fill this form.