At Mikon Machinery, we provide state-of-the-art CNC machines tailored to various industries. Our technology ensures precision, efficiency, and reliability for all your fabrication and manufacturing needs. From intricate designs to robust manufacturing, our CNC machines excel in diverse tasks. Explore below how our industry-specific solutions can elevate your projects.

When seeking the right equipment for your industry, turn to the experts who understand your unique needs. At Mikon Machinery, we deliver high-quality, performance-driven CNC machines suited for a variety of industries and applications. Trust us to help you find the perfect CNC solution.

By purchasing your CNC machine from Mikon, you gain more than just quality equipment. Included with your purchase is initial startup support and unlimited phone and email support. Get the equipment you need paired with expert-level support from Mikon Machinery.

Mikon Machinery Group provides a diverse range of CNC machines, enhancing the application of CNC machines in the woodworking industry. These CNC woodworking machines are known for boosting efficiency, precision, and versatility, making them indispensable tools in modern woodworking shops. Our lineup includes advanced automation tools for loading, unloading, labeling, and integrating with production scheduling software, ensuring high-quality production outcomes.

Industries that take advantage of CNC to improve automation and increase operational efficiencies:

Cabinet Making, Furniture Manufacturing, Wood Carving, Architectural Millwork, Windows and Doors, 3D Carving, Solid Surface countertops, Sign Making, Prototyping and more.

CNC routers are often used for manufacturing cabinets, closets doors, fixtures and decorative inlays Intricate inlays and marquetry work can be created with precision and consistency. With the right software, you can complete more complex tasks such as nesting for greater operational efficiencies. Dowel and Tenon Production? With optional and onboard features, you can complete milling and drilling operations with high accuracy.

Woodworking prototypes can be quickly and precisely created with CNC technology, allowing woodworkers to test their designs before committing to full-scale production.

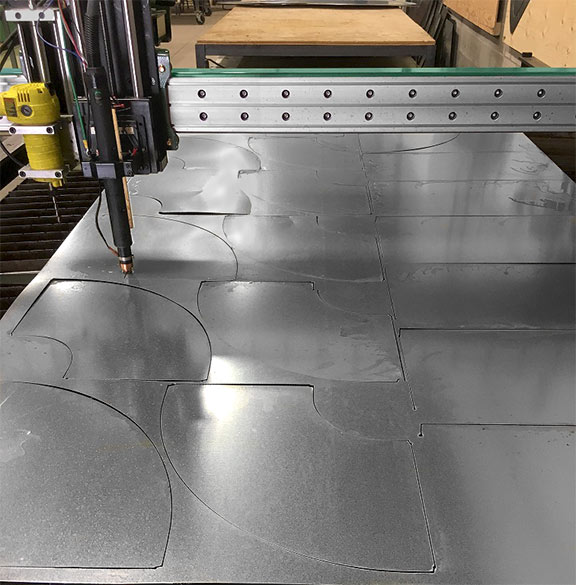

Mikon Machinery Group offers an assortment of CNC cutting machines that are geared to serve the HVAC industry fabrication requirements. Our lineup of CNC plasma and laser cutting machines can be employed to cut various materials used in HVAC systems, such as sheet metal and insulation materials. These machines offer high precision and can cut intricate shapes quickly.

CNC technology has become increasingly prevalent in the HVAC (Heating, Ventilation, and Air Conditioning) industry for various fabrication processes. CNC capabilities in HVAC fabrication supply several advantages, including precision, consistency, efficiency, and the ability to handle complex designs. Here are some of the key applications and capabilities of CNC technology in HVAC fabrication. CNC machines can be integrated with quality control processes to ensure that fabricated HVAC components meet industry standards and specifications. CNC technology improves production efficiency by reducing material waste, minimizing human error, and allowing for lights-out manufacturing, where machines can operate 24/7 with minimal human intervention.

CNC advantages for the HVAC Community:

CNC machines can be used to cut sheet metal to produce ductwork components. This ensures precise and correct dimensions, leading to improved system performance and reduced air leakage.

HVAC system prototypes and custom components can be fabricated using CNC laser or plasma. This allows for the testing of modern designs and innovations in a controlled and accurate manner.

CNC technology plays a pivotal role in the application of CNC machines for creating intricate and customized grilles and registers in HVAC systems, enhancing both functionality and aesthetic appeal. Additionally, CNC knife cutters excel in cutting insulation materials to precise dimensions, ensuring HVAC systems are optimally insulated for superior energy efficiency and thermal control.

Mikon Machinery Group offers an assortment of Plasma, Waterjet, Fiber Laser and CO2 Laser CNC cutting machines capable of meeting the needs of the most complex application for metal plate fabrication. Depending on material thickness, accuracy needed, and largest allowable taper, we can recommend the correct Fiber Laser or High-Definition plasma machine.

Industries that take advantage of CNC to improve automation and increase operational efficiencies:

Mining

Automotive

Transportation

Construction

General Fabrication

Several types of metal plates, including steel, aluminum, stainless steel, and more. The specific CNC equipment and tooling may vary based on the material being processed. CNC offers high levels of accuracy and repeatability, ensuring that the finished products meet tight tolerances and specifications. Our plasma systems are available with either downdraft or water table configurations to control smoke and dust. Fiber laser systems are offered with efficient filtration systems to clean debris and smoke from the cutting process.

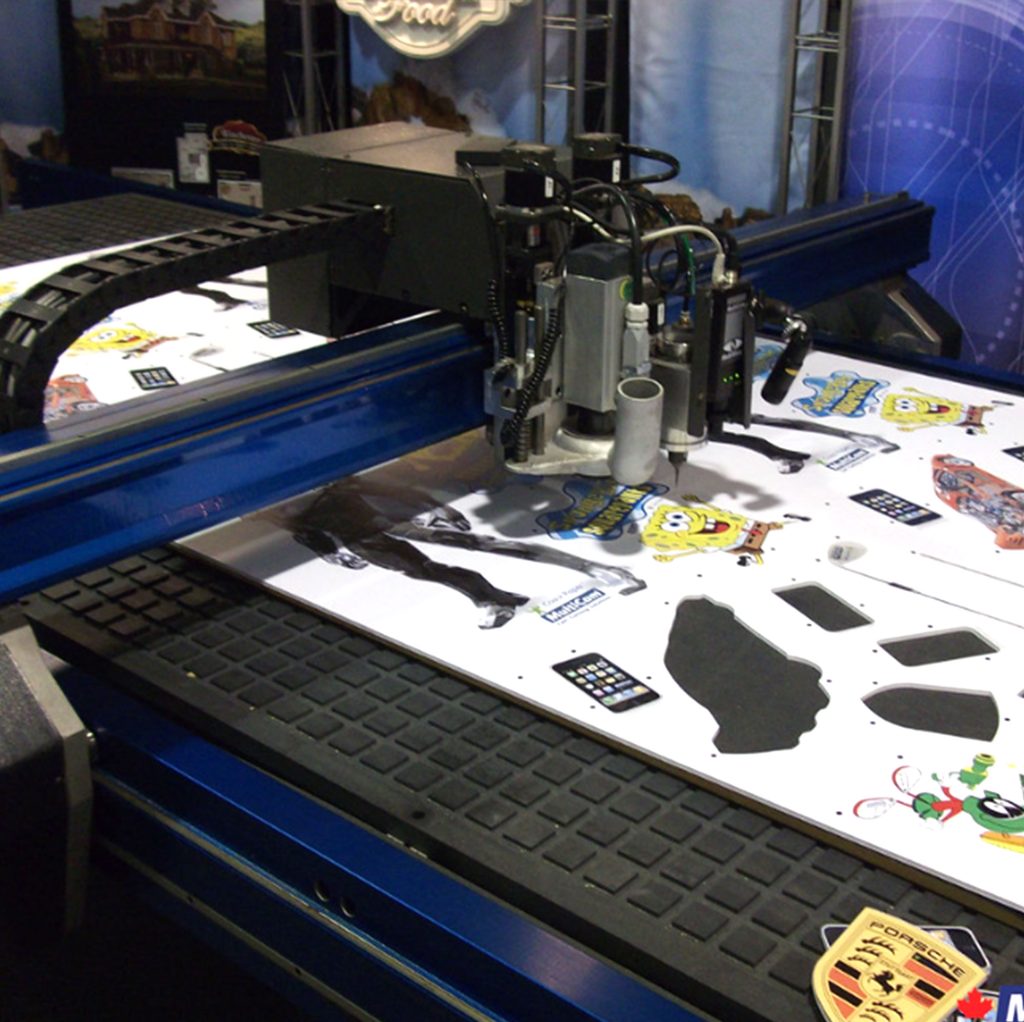

Mikon Machinery Group offers a wide variety of CNC cutting machines tailored to the sign fabrication industry, including knife cutting as well as combo router/knife cutting machines.

CNC routers, lasers and knife cutters can accurately cut various materials commonly used in sign fabrication, with Multi-Material Compatibility, the right CNC will help automate fabrication processes for many materials, including, wood, plastic, metal, foam, acrylic, and more, allowing for precise shapes and intricate designs. CO2 lasers are also offered and commonly used for cuttig acrylics in the sign industry.

Mikon Machinery provides equipment to the Stone /Tile cutting industry as well as the glass industry in the form of Abrasive waterjet MJT 3 axis and MJT 5 axis models. The stone industry can cut any imaginable shape in granite , quartz, marble, and other natural stone materials. Abrasive waterjet can be used for sink cutouts, faucet holes, as well as bevelled edges for a striking appearance. The additional functionality of a 5 axis cutting head allows for tapers up to 60 degrees from vertical. Tile inlays can be easily manufactured on the MJT 3 axis waterjet to tight tolerances, ensuring a great fit every time.

Glass fabrication companies utilize waterjet machines for shower doors, custom cutouts, thick / bulletproof glass types, and complex architectural glass inlays. The MJT waterjet machines feature special low pressure piercing strategies to minimize the chance of glass shattering during the initial pierce. Our technicians will also be happy to work with you to learn how to minimize frosting, chipping and other potential issues that can occur during cutting this brittle material.

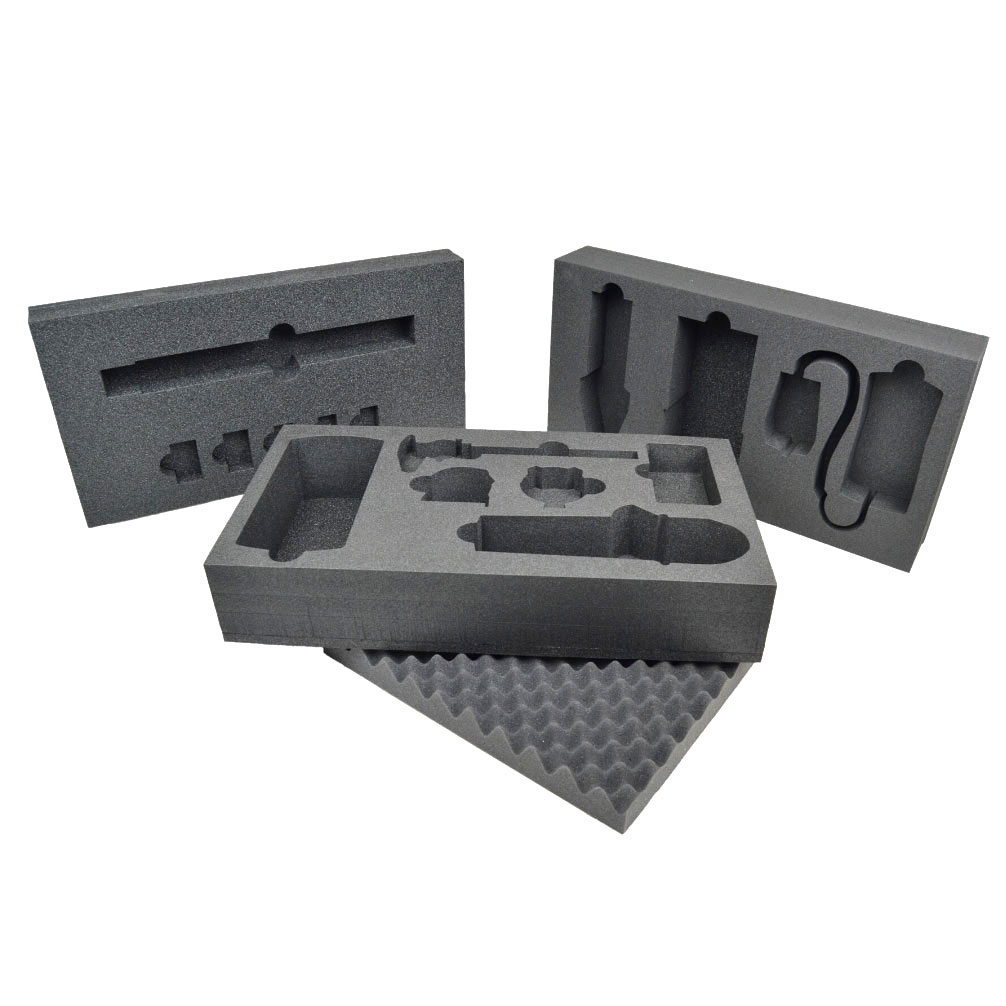

Various grades and thicknesses of foam are used in the packaging industry worldwide. Foam cutting is generally done by one of two common processes, both of which can be done on equipment from Mikon Machinery Group. When full depth profiles are needed, waterjets using pure water (no abrasive) are commonly used. Since foam is a low density material, abrasive is not needed, greatly lowering the operating cost compared to abrasive waterjet cutting. Foam can be cut using pure water up to 75mm thick with minimal taper.

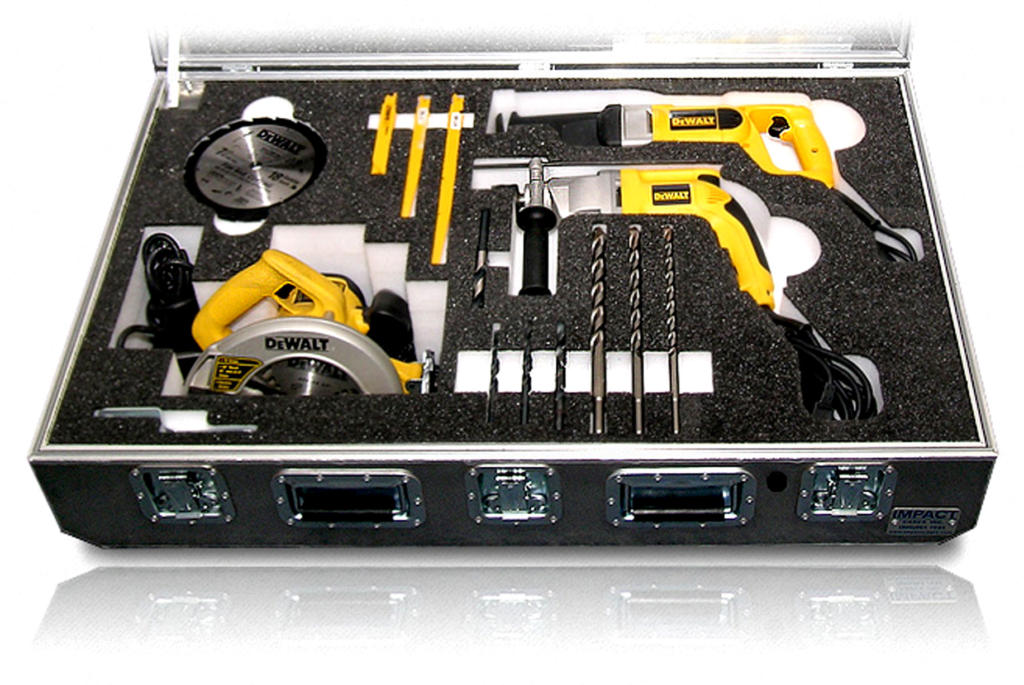

Most of our packaging/foam industry customers utilize multi head machines that have 3-4 cutting heads, cutting multiple pieces at once. Some types of foam packaging require partial depth cuts/pockets, often used for case goods , cameras, military optics and more. In situations where only a partial depth cut is needed (pocketing) a CNC router or CNC router/knife cutting combo machine is utilized. Oscillating knife can quickly finish the walls of foam pockets, while a router bit can quickly remove the material in the middle of the pocket. Dust collection systems around the spindle allow for fast clean up of chips, ensuring minimum downtime. Contact us today to discuss your foam cutting application!

Equipment Case manufactured by our customer Impact Cases in Markham ON

Mikon Machinery offers a comprehensive selection of CNC tools and parts, including router bits, knife blades, saws, desktop cutters, OEM parts, and consumables, sourced from trusted brands like Amana Tool, LMT Belin, X-Edge, Dimar, and Whiteside. Our partnerships ensure access to high-performance tools, such as end mills, drilling tools, toolholders, and control systems, designed for precision and durability across industries like woodworking, metal fabrication, and stone cutting. With our expertly curated selection, your CNC operations will consistently achieve optimal results.

Sign-up for our newsletter!

Select the newsletter category you would like to receive

Machines

Contact Us

Copyright Mikon Machinery ® LLC 2024. All Rights Reserved. | Designed by CNC Marketer

Join Our Newsletter

We know your inbox is full of sales pitches. We take a different approach. Our emails focus on what matters to you, like choosing the right spindle HP and essential maintenance tips. For joining us and staying informed, simply fill this form.