The Evolutionary Journey of Fiber Laser Technology

Since its introduction in the 1960s, fiber laser technology has undergone a radical transformation. Initially developed for telecommunications, the continuous advancements in this technology have expanded its power, efficiency, and reliability. Modern fiber lasers, capable of high-power output, have broadened the scope of industrial applications, making them indispensable for precision manufacturing. For a more detailed historical perspective, you can read more about the advancements in laser technology at the International Society for Optics and Photonics (SPIE).

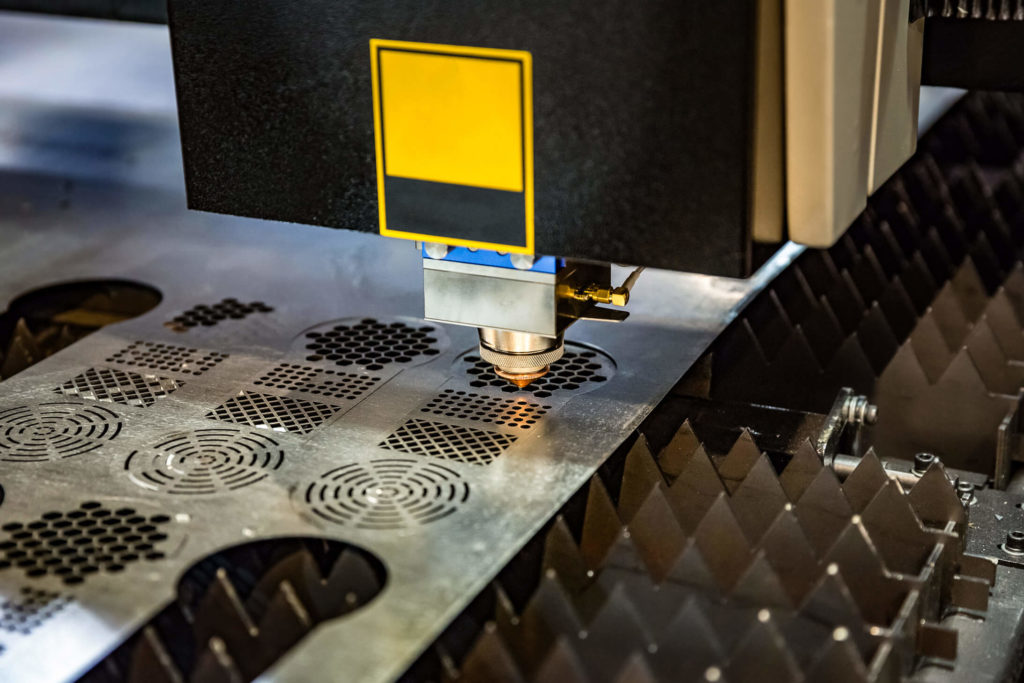

Distinct Advantages of Fiber Laser Machines

Fiber laser machines stand out for their exceptional operational efficiency, versatility in material handling, and unparalleled precision. These machines redefine manufacturing benchmarks, enabling intricate designs and maintaining high quality even in demanding production environments. The significant advantages include:

- Speed: Fiber lasers dramatically reduce processing times, allowing for faster completion of projects and increased throughput.

- Precision: The technology is renowned for its accuracy, producing intricate cuts that traditional methods cannot achieve.

- Flexibility: Capable of handling various materials and thicknesses, fiber lasers adapt seamlessly to diverse manufacturing needs.

- Economical: With minimized waste and lower maintenance requirements, fiber lasers offer cost-effective solutions for manufacturers.

Impacting Diverse Manufacturing Sectors

The versatility of fiber laser technology has facilitated its adoption across multiple industries. In sectors like aerospace, automotive, and electronics, where precision and efficiency are paramount, fiber lasers have become a critical component of the manufacturing process. These machines enable the production of complex parts, meeting the exacting standards of modern industry.

Navigating the Fiber Laser Market in Canada

The Canadian market for fiber laser machines is witnessing significant growth, fueled by the demand for advanced manufacturing solutions. Government incentives, a burgeoning manufacturing sector, and an emphasis on high-quality, sustainable production have all contributed to the increased adoption of fiber laser technology. Manufacturers looking to stay competitive are turning to fiber lasers for their proven benefits in improving productivity and reducing environmental impact.

Selecting the Right Fiber Laser Machine

Choosing the most suitable fiber laser cutting machine for your business involves careful consideration of several key factors:

- Material and Thickness: Assess the typical materials and thicknesses your operations require to ensure compatibility.

- Power Output: Match the machine’s power output with your cutting needs, considering the range of materials you process.

- Precision and Control: Opt for machines known for their precision and equipped with advanced software for seamless operation.

- After-Sales Support: Ensure your supplier provides comprehensive after-sales service to maintain your machine’s optimal performance.

Future Prospects of Fiber Laser Technology

The advancement of fiber laser technology is on an unstoppable upward trajectory, characterized by a relentless drive toward innovation and excellence. As we look ahead, the horizon is vibrant with the promise of breakthroughs that will redefine manufacturing efficiencies, precision, and capabilities. This section delves into the anticipated developments in fiber laser technology and the strategic implications for manufacturers aiming to capitalize on these advancements.

Unveiling Next-Generation Innovations

The future of fiber laser technology is set to unfold through a series of transformative innovations. Key among these is the evolution of ultra-high-power fiber lasers, expected to significantly enhance cutting speeds while maintaining impeccable precision. This leap in power output will enable the processing of thicker and more challenging materials with ease, expanding the scope of applications across industries.

Another anticipated advancement is the integration of artificial intelligence (AI) and machine learning algorithms into fiber laser systems. This integration promises to revolutionize the way fiber lasers operate, enabling predictive maintenance, optimizing cutting paths in real-time, and automatically adjusting parameters for optimal efficiency and quality. The result is a smarter, more autonomous manufacturing process that reduces human error and maximizes productivity.

Expanding Material Capabilities

As fiber laser technology progresses, so too does its versatility in material processing. Future developments are expected to broaden the range of materials that can be precisely cut or engraved, including composites, advanced alloys, and potentially even non-traditional materials for laser processing. This expansion will open new avenues for innovation in sectors like aerospace, where cutting-edge materials require equally advanced manufacturing technologies.

Sustainability at the Forefront

The next wave of fiber laser technology innovations will also emphasize sustainability. Advances in energy efficiency and reduced consumable use will further diminish the environmental footprint of manufacturing operations. Manufacturers will not only benefit from lower operational costs but also align with increasing regulatory and societal demands for sustainable practices.

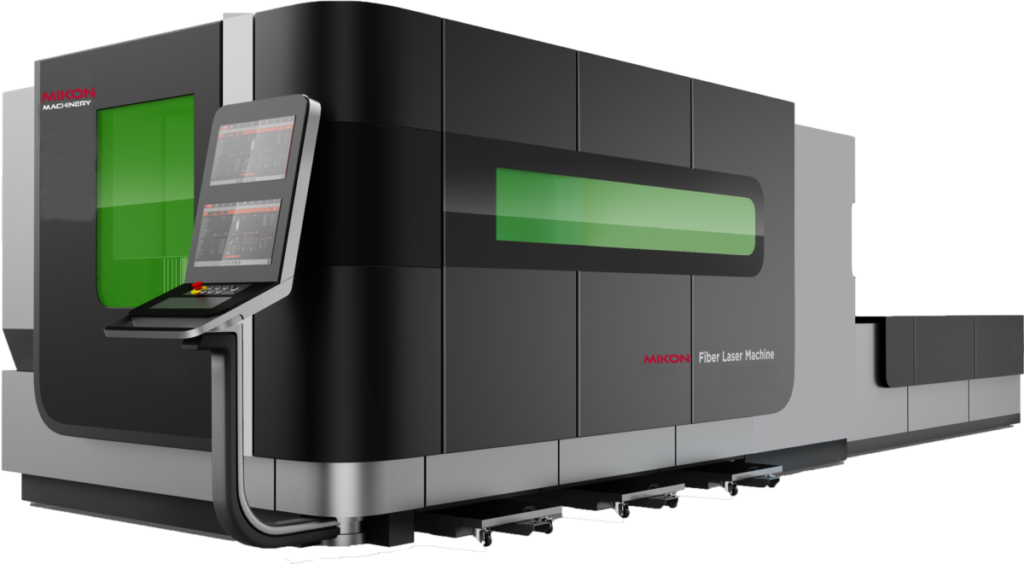

Preparing for the Wave of Innovations

For manufacturers, staying ahead in the rapidly evolving landscape of fiber laser technology necessitates a proactive approach. Investing in ongoing training and development for teams is crucial to fully leverage the potential of new fiber laser advancements. Furthermore, forging partnerships with leading fiber laser technology providers like Mikon Machinery will ensure access to the latest innovations and support services, keeping manufacturing processes at the cutting edge.

Conclusion: Elevating Manufacturing with Fiber Laser Precision

Fiber laser technology is transforming the manufacturing industry, offering solutions that enhance precision, efficiency, and sustainability. As the demand for advanced manufacturing technologies grows, the role of fiber lasers becomes increasingly critical. For businesses seeking to leverage these advancements, investing in fiber laser technology represents a strategic move towards future-proofing their operations and achieving unparalleled success in the competitive market.