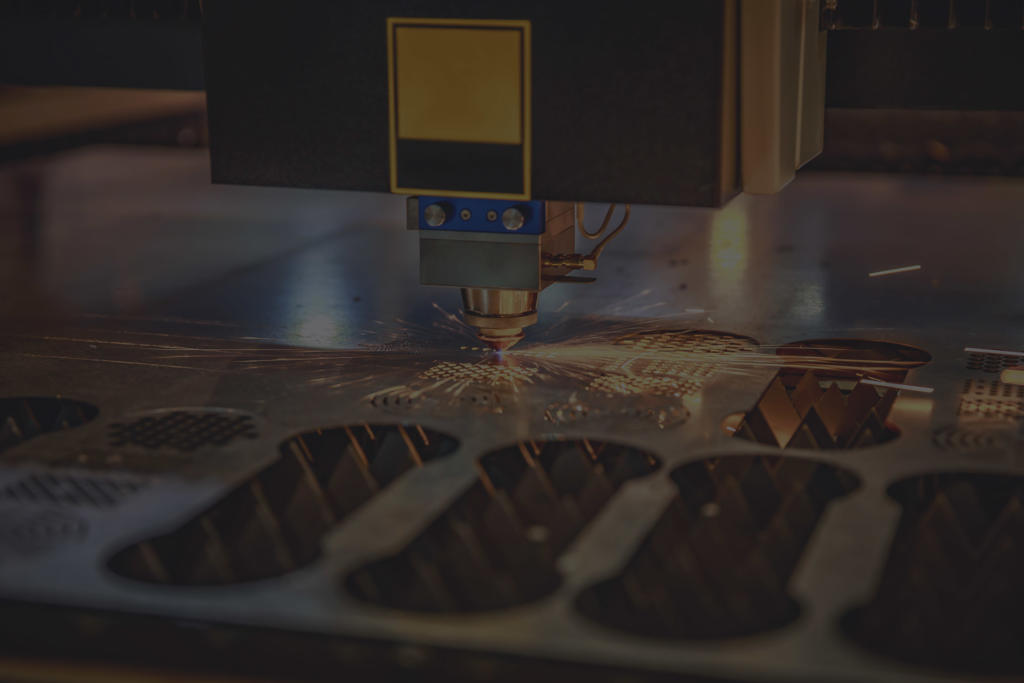

What is Fiber Laser Cutting Technology?

The fiber laser cutting machine is revolutionizing manufacturing, delivering unparalleled precision, speed, and efficiency. This technology, with its powerful, focused beam, offers seamless cuts across diverse materials, producing clean, efficient results. Its reliability across various tasks—from intricate designs on thin sheets to slicing through thick, industrial materials—sets it apart.

What distinguishes the fiber laser machine is its superior energy efficiency, low maintenance, and quicker operation than traditional methods. Its precise laser beam minimizes heat distortion, ensuring accurate cuts that preserve material integrity. Additionally, it’s adept at cutting challenging materials like copper and brass, showcasing its versatility.

Looking ahead, the fiber laser cutting machine is undergoing significant advancements. Anticipated improvements in 2024 include increased laser power, better automation, and improved software integration, which enhance its cutting capabilities and ease of use. These advancements are expected to lead to faster production times, lower energy consumption, and the ability to work with an even wider range of materials. Companies investing in the latest fiber laser cutting technology are set to elevate their manufacturing processes and maintain a competitive edge.

Key Considerations Before Buying a Fiber Laser Machine

Before investing in a fiber laser cutting machine, it’s essential to consider several key factors that will ensure the machine aligns with your business needs and financial capacity. These considerations form the foundation for making an informed purchasing decision that will benefit your operations in the long run.

Assessing Your Business Needs and Objectives

Start by evaluating the scope of your projects, including the types of materials you’ll be cutting and the expected production volume. Consider the level of precision required for your work and how the machine’s capabilities will support your business’s growth and adapt to future projects. This assessment will help you identify the specifications and features most critical to your operations.

The Financial Aspect: Budgeting for Your Machine

Beyond the upfront cost of the fiber laser machine, it’s vital to factor in ongoing expenses such as maintenance, replacement parts, and operational costs. Establishing a comprehensive budget that accounts for these long-term financial commitments will ensure you choose a machine that not only fits your current financial situation but also offers sustainable value over time.

Exploring various financing options can also ease the initial financial burden, allowing you to invest in technology that propels your business forward without straining your resources. Explore our in-house financing solutions for a seamless purchasing experience. Our tailored financing options are designed to help you manage your budget effectively while securing the technology you need for your business to thrive.

Features to Look for in a Fiber Laser Cutting Machine

Selecting the best fiber laser cutting machine involves focusing on features that match your manufacturing needs, combining technical specifications with practical functionality to enhance your production workflow.

- Cutting Speed and Efficiency: The speed of a CNC fiber laser machine is crucial, as it directly affects how quickly tasks can be completed, influencing overall productivity and operational costs. A model renowned for its quick cutting capabilities and efficient power use can dramatically increase production rates while minimizing costs associated with energy and material consumption.

- Machine Build Quality and Durability: The construction quality of a fiber laser cutting machine is a significant determinant of its operational lifespan and the consistency of its cuts. Machines built to high standards maintain accuracy over time and are less likely to be affected by vibrations, which could compromise the quality of cuts. A durable machine promises longevity, reducing the need for frequent repairs and ensuring continuous operation.

- Software Compatibility and Ease of Use: The software driving a laser cutter plays a vital role in operational complexity and user-friendliness. Compatibility with existing design and production software broadens the machine’s utility, while an intuitive user interface simplifies training, reduces the likelihood of operator errors, and improves overall productivity.

Types of Fiber Laser Machines

The market offers a variety of fiber laser cutters, each designed to cater to specific manufacturing needs and material handling capabilities. Understanding the differences between these types and their applications can help you select the most suitable machine for your business.

Comparing Different Models and Their Applications: Fiber laser machines vary significantly in terms of power, size, and functionality. Some models are optimized for high-speed cutting of thin metals, ideal for industries requiring precision parts at a fast pace. Others boast higher power outputs, capable of slicing through thick industrial-grade materials with ease. Compact models are available for businesses with limited space, maintaining high efficiency without occupying a large footprint.

Model Type | Application | Best For |

High-Speed | Thin metals, detailed work | Precision industries |

High-Power | Thick materials | Heavy-duty manufacturing |

Compact | Space-sensitive environments | Small workshops |

Specialized Machines for Diverse Material Handling: Beyond general models, there are specialized fiber laser machines designed for specific material types or dual purposes. For instance, some machines excel at cutting reflective metals like copper and aluminum without damage to the system, a task challenging for traditional lasers. Dual-function machines can handle both sheet metal and tubular materials, providing versatility and expanding the range of projects a business can undertake.

Machine Type | Specialty | Ideal Use |

Reflective Metal Cutters | Copper, aluminum | Industries using varied metals |

Dual-function | Sheets and tubes | Versatile manufacturing needs |

By evaluating the types of fiber laser machines and considering their specific applications and material handling capabilities, you can make a well-informed decision that aligns with your manufacturing requirements and goals. Whether you need a machine for detailed, high-speed work or one that can manage a variety of materials, there’s a fiber laser cutting machine designed to meet those needs.

Evaluating Machine Performance and Precision

Ensuring your fiber laser machine operates at peak performance involves more than just evaluating its specs; calibration and alignment play a crucial role in maintaining precision in every cut. Proper calibration ensures that the laser cutter produces accurate and consistent results, minimizing errors and waste.

Furthermore, the integration of advanced technology enhances the machine’s capabilities, allowing for superior output. Innovations such as improved laser power, sophisticated software algorithms, and automated material handling systems not only boost efficiency but also expand the range of materials that can be processed with precision, making the machine a versatile tool in any manufacturing setting.

Long-Term Maintenance and Operational Costs

To make a wise investment in a fiber laser cutting machine, it’s crucial to look beyond the purchase price. Future-proofing your operations involves a clear plan for ongoing maintenance and securing a stock of essential spare parts to avoid costly downtimes. Equally important is grasping the broader financial picture, which includes energy usage, regular upkeep, component replacements, and operator training. This holistic view of expenses helps businesses gauge the true value the machine brings over its lifespan, ensuring a decision that balances initial outlay with long-term benefits and operational efficiency.

Making the Right Choice: Tips from Industry Experts

Industry experts often emphasize the significance of after-sales service and support when choosing a CNC laser cutting machine. Exceptional support from the manufacturer can make a significant difference in the machine’s operational efficiency and longevity. Reliable after-sales service ensures that any technical issues or maintenance needs are addressed promptly, keeping downtime to a minimum and preserving productivity.

Gathering feedback and reviews from existing users is another crucial step in making an informed decision. Insights on the machine’s real-world performance, durability, and the quality of the manufacturer’s customer service provide valuable perspectives that go beyond product specifications. Hearing about other users’ experiences can highlight potential strengths and weaknesses, helping you anticipate how the machine will fit into your operations and meet your long-term needs. This approach allows you to leverage collective experiences, ensuring your investment is backed by a community of users.

Final Thoughts: Investing in the Future of Your Business

Investing in a fiber laser cutter represents a strategic decision that propels your business into the future. The precision, efficiency, and versatility offered by these machines provide a competitive edge, enabling you to meet the demands of your clients swiftly and with unparalleled quality. This technology not only enhances your manufacturing capabilities but also positions your business as a forward-thinking player in the industry, ready to tackle complex projects with confidence.

The journey towards integrating this advanced machinery into your operations begins with selecting a reputable manufacturer. A trusted partner ensures you receive not just a high-quality machine but also comprehensive support, from installation to after-sales service. This relationship is crucial for maximizing the return on your investment and ensuring your machine remains a vital asset for years to come.

Ready to Elevate Your Manufacturing Process? Discover how Mikon CNC Fiber Laser Machines can transform your production line. Visit Mikon CNC Fiber Laser Machines to explore our cutting-edge solutions tailored to meet the diverse needs of modern manufacturing. Embark on this journey with us and harness the strategic advantage of the latest fiber laser technology.