What Your CNC Router Can Achieve

The adaptability of CNC cutters to work with a diverse range of materials marks a significant advancement in manufacturing and design processes. From soft woods to hard metals and even delicate plastics, the scope of materials that can be precisely cut and shaped is vast. This versatility not only expands the creative possibilities for designers and fabricators but also enhances the operational efficiency of industries relying on these materials.

From Wood to Metals: The Extensive Range of CNC-Compatible Materials

CNC routers, with their precision cutting capabilities, can handle an impressive spectrum of materials. Wood, a traditional favorite, benefits from the router’s ability to execute intricate designs and smooth finishes. Metals, including aluminum and stainless steel, can also be cut with precision, opening doors to applications in automotive, aerospace, and architectural industries. Plastics and acrylics are equally important; their versatility under the CNC router’s touch allows for applications ranging from signage to POP displays and even prototype development.

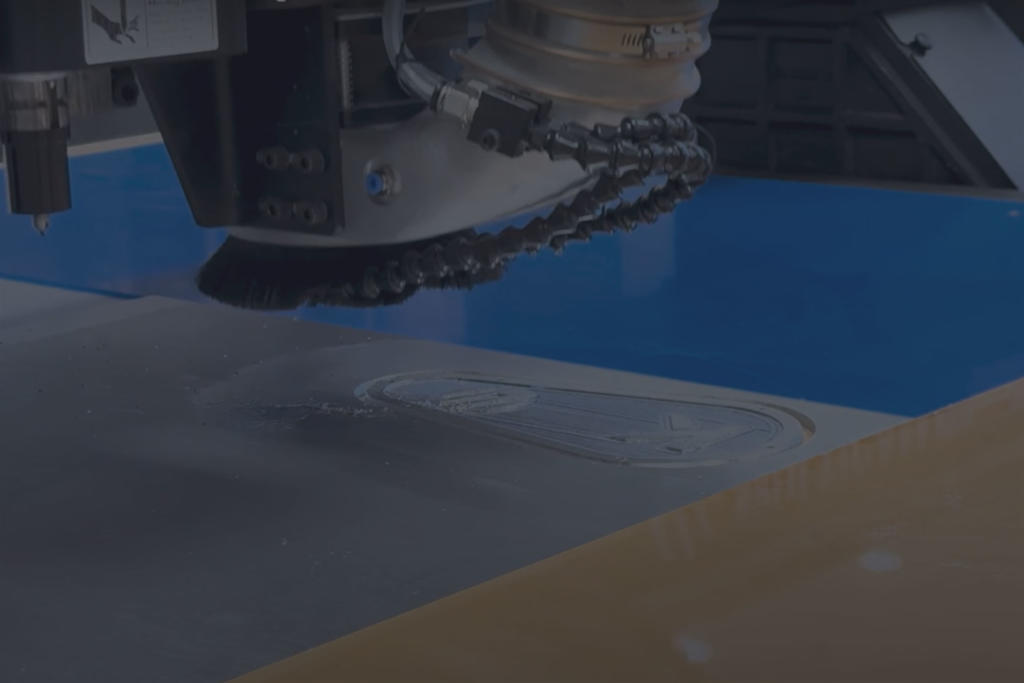

The Technology Behind Precision: How CNC Routers Transform Material Cutting

Behind every precise cut and every smooth finish is advanced technology that powers CNC routers. The combination of powerful software and robust hardware allows these machines to execute complex designs with high precision. The software component, in particular, plays a crucial role, converting digital designs (CAD) into precise cutting paths (CAM). This technological synergy ensures that regardless of the material complexity or thickness, the output remains consistent and of high quality.

Optimizing Your CNC Router: Insights and Strategies for Industrial Innovators

To fully harness the potential of CNC cutters, understanding how to optimize the machine’s settings and operations is key. This involves selecting the right tools for the job, understanding the material properties, and mastering the software that drives the router’s operations. Through strategic optimization, businesses can achieve higher productivity, reduce waste, and enhance the quality of their output.

Selecting the Right Router Bits for Your Material Type

The choice of router bits is critical in achieving the desired results on different materials. Each material requires a specific type of bit to optimize cutting efficiency and quality. For instance, cutting acrylics demands bits that prevent melting or chipping, while hardwoods require bits designed to minimize tear-out and ensure smooth edges. Understanding these nuances and selecting the appropriate bits can significantly impact the success of your projects.

Mastering Material Cutting with CNC Routers: Techniques and Tips

Beyond selecting the right tools, mastering the CNC machine involves understanding the best practices for material cutting. This includes securing materials properly to prevent movement during cutting, adjusting the router’s speed and feed rate to match the material, and designing cutting paths that minimize waste & optimize material yield. Practicing these techniques enhances not only the precision of the cuts but also the efficiency of the material usage, leading to better outcomes and higher satisfaction in the final products.

Real-World Successes with CNC Router Technology

The impact of CNC router technology extends beyond theoretical advantages, as demonstrated by numerous success stories across various industries. These case studies highlight the practical benefits and transformative potential of CNC routers, offering valuable insights and inspiration for businesses looking to innovate and improve their operations.

Transforming Industries: CNC Routers in Action

From small workshops to large manufacturing plants, CNC routers have played a pivotal role in transforming business operations over the last few decades. In the furniture industry, for example, businesses have leveraged CNC routers to produce complex designs with high efficiency, significantly reducing production times while enhancing product quality. Similarly, in the sign-making industry, the precision of CNC cutters has enabled the creation of intricate and durable signage that stands out in competitive markets.

Achieving Excellence with CNC Routers

Experts in the field of CNC routing often share key insights into achieving excellence with these machines. From optimizing machine settings for different materials to adopting innovative design techniques, their advice can guide businesses in fully leveraging CNC router technology. Incorporating expert strategies into daily operations can lead to improved efficiency, creativity, and competitiveness in the marketplace.

Elevate your manufacturing and design processes with the precision and versatility of CNC routers. Discover the latest in CNC cutting technology tailored to meet the unique demands of your industry at Mikon Machinery. Explore our range of CNC routers and let our experts guide you in selecting the perfect machine to boost your productivity and creativity.

In closing, the adoption of CNC router technology marks a pivotal moment for enhancing production and innovation within various industries. Through strategic utilization, companies can achieve unprecedented accuracy and versatility in material processing, setting new standards for efficiency and creativity.